Sustaining RMG industry growth by Md Ridwanul Huq

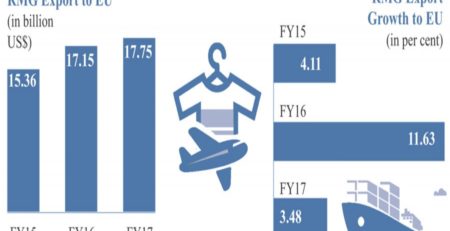

The RMG industry has been at the helm of Bangladesh exports for over the years and a significant contributor to GDP. This industry has, till date, absorbed an estimated 4.4 million people, of whom 80 per cent are women, helping both economic growth and social development in Bangladesh. A host of favourable factors have driven robust growth – the primary factors being the availability of large and cheap labour pool. RMG is a labour-intensive industry with fairly simple manufacturing process. So, the new workers could easily pick up skills in a short span and specialise gradually. However, multitude of bottlenecks, such as infrastructural deficits, policies, high lead time etc., have restricted its expected growth. The RMG industry’s steady growth has encouraged Bangladesh to set an ambitious export target of $50 billion by 2021. However, export growth in recent years has been declining. According to Export Promotion Bureau (EPB) data, RMG exports in the first eight months of the current fiscal year (FY 2016-17) stood at $28.09 billion, which is 5.64 per cent lower than the target of $30.38 billion. Achieving the $50 billion target would necessitate export growth of more than 12 per cent, but it currently hovers around three per cent. Factors like movements of buyers to other RMG destinations, like Vietnam and India, increased facilities to the RMG sector in several Asian nations, gradual fall in prices in importing nations and internal chaos are affecting the competitiveness of Bangladeshi RMG exporters. Moreover, according to Bangladesh Garment Manufacturers and Exporters Association (BGMEA), in the last two years, production cost has increased by up to 17 per cent due to gas crisis, devaluation of euro and price fall in EU and US markets, on the back of the US election and Brexit.The government, policymakers and entrepreneurs are mainly concerned with rising labour costs and export restrictions but have been overlooking few important factors vital to sustaining this growth. They are not actively considering positive image branding of this industry which can possibly boost sales by attracting foreign buyers and many manufacturers are not considering branding our local fashion/retail industry. On the other hand, skilled human resources — one of the biggest factor which greatly adds to cost – was also not being addressed until recently. These two factors must be considered for long-term growth of the industry. Even if Bangladesh loses competitive edge in terms of cheap labour, cutting costs in other areas and boosting sales can effectively help manufacturers maintain their existing margin and can even raise it.Bridging skill gap: Skill gap has been a serious issue from the very beginning. Due to unprecedented growth and huge demand of cheap Bangladeshi RMG in the beginning, manufacturers and the authorities simply focused on boosting sales by offering lower prices and largely ignored skill development. Skill gap is a situation where employers are hiring workers whom they consider under-skilled or that their existing workforce is under-skilled relative to a desired level. Bangladesh already has comparatively lower worker productivity rate amongst competing nations, which has been further aggravated by skill gaps and shortages at all level.Researches and studies suggest that there is a serious gap in skills all around in RMG sector starting from workers to operators, mid to top-level managers, trainers, as well as entrepreneurs. As of 2015, an estimated 200,000 foreigners working in industries in Bangladesh remitted $5 billion annually, majority of them are occupying supervisory and managerial positions. This greatly adds up to the cost of manufacturers. Given the current situation of worker unrest, compliances and strict requirements from buyers, manufacturers are bound to cut down their product margin to bear with these added expenditures.As per Bangladesh Institute of Development Studies (BIDS) report, demand for skill labours in approximately 10 years will be as high as 122 per cent. If the skill gaps are not addressed by that time, the productivity will be hampered and Bangladesh will lose its edge with available pool of labour.Branding RMG industry: “Branding RMG” has been a notable issue in recent years, especially after the “Rana-plaza disaster” and “Tazreen Garments Fire” which killed thousands of RMG workers and formed a negative image of RMG industry of Bangladesh. Experts have urged garments owners and the authorities concerned to invest in positive brand-building of this industry. However, this concept still remains unappreciated. Even if some owners reluctantly agree to invest, many of them still consider this a waste of resources. One of the most important reasons behind this thought process is that the industry is still headed by first-generation entrepreneurs who barely grasp the concept and importance of brand-building. These entrepreneurs have been making enough profits just by being suppliers of readymade garments and never had to care about branding since buyers would be attracted by cheap labour anyway. They definitely do not realise that increasing labour costs and globally unfavourable image of Bangladesh is driving buyers to other destinations and only a good image-branding can reverse the situation. Fortunately, few big manufacturers and exporters, many of them led by second-generation entrepreneurs, are investing in brand-building. In fact, they have gone a step ahead and started creating local retail brands, few of which have gained a footing in the international market and opened up a new arena in RMG exports. These local brands have reportedly helped the country to cut the import of apparel items to the minimum level. The new entrepreneurs have been able to maintain quality within affordable price range by using local resources. Approximately 60 per cent of fabrics and accessories are now produced locally by industries based in EPZs or elsewhere while only a decade ago, the industry had to import majority of these items. Many local factories are producing quality cotton, twill and denim fabrics which are being sourced by international brand, giving the local retail brands the advantage of sourcing best resources at the lowest cost, enabling margins to grow significantly. Local brands like “Yellow” (a concern of Beximco Textiles) can now command higher prices in international markets where they have expanded and sustain their business despite higher labour and compliance costs. “Aarong” is soon to join the league to internationalise their brand.Dr Md Ridwanul Hoq is the Chairman of BBA Program, Institute of Business Administration, University of Dhaka.

Dr Md Ridwanul Hoq is the Chairman of BBA Program, Institute of Business Administration, University of Dhaka.