Opportunity coming Kenya’s way in global garments trade by Mehdi Mahbub

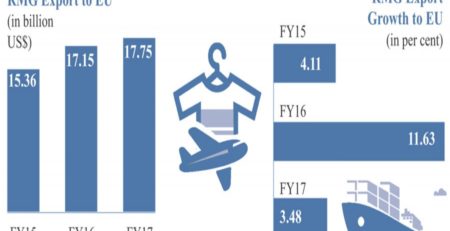

Kenya is rapidly becoming one of the biggest players in the world’s textile manufacturing industry, and is tipped to be one of the next centres for apparel sourcing in East Africa alongside Ethiopia.For decades, the global garment industry has been dominated by the powerhouses in Asia-China, Bangladesh, Vietnam, India, Pakistan, Taiwan, Korea etc. However, the growth of Asian industry and its dominance have come under increased threat in recent years. Several Asian producers are switching over to a more service sector-based economy from the manufacturing-based one. China – the world leader – has started to embrace a more service sector-based economy. It is predicted that the number of Chinese manufacturing jobs will be cut down by 85 million by 2030. This coupled with the rising production costs in Asia has contributed to the recent decline of the garment sector in the Asian market. Kenya is among the front-runners to make the most out of this opportunity and fill in the void left in the market by the Asian Tigers.With an area of 581,309 square kilometrs and a population of around 47 million, the Republic of Kenya is a leading country in Africa. Its capital and largest city, Nairobi, has been dubbed the hub for East Africa for long. It is a founding member of the East African Community (EAC). Kenya gained its independence on December 12, 1963 from its colonial ruler, the United Kingdom.Kenya’s private sector is one of the most advanced and dynamic in Sub-Saharan Africa. Cotton production was introduced in Kenya in the 1900s by the colonial administration. To protect the local cotton industry, the Kenyan government introduced 100 per cent duties on imports after independence. The industry was also heavily subsidised.The 70s and the period up until the mid 80s, the Kenyan textile industry experienced a rapid growth. However, this boom didn’t last very long. It had already started declining alarmingly from the mid 80s and by the 90s the textile industry collapsed altogether. The availability of used clothes – locally known as “mitumba” – at a very cheap price crippled the textile industry and was the sole reason behind the sudden fall of the garments industry. The textile industry in Kenya transformed once again in the 2000s, and this time it transformed for the better, thanks to Kenya’s inclusion in the African Growth and Opportunity Act, or AGOA for short. Kenya was the first African country to be accredited as an AGOA beneficiary. AGOA presented the Kenyan textile industry with a much-needed lifeline as it opened the doors to huge market prospects. Since Kenya’s inclusion in AGOA, in a mere six-year period (2000-2006), Kenya’s clothing sales to the United States alone increased from US$44 million to US$270 million.Since joining AGOA, Kenya’s impressive performance in the global markets has attracted a significant amount of foreign direct investments in the textile industry. And why wouldn’t someone invest in Kenya? In numerous ways Kenya is the ideal investment ground for the investors. Kenya has a ready farming community which only requires enough seeds and irrigation schemes to be put in place. The climate of Kenya is also ideal for growing cotton as cotton grows well in semi-arid areas. Kenya also offers large areas of cultivable land mass for cotton. Kenya has abundant and relatively well-educated population. Therefore, skilled and unskilled labour forces are readily available at reasonable rates. The manufacturing industry in Kenya is vibrant enough to absorb all the cotton production, which ranges from ginneries to garments manufacturing. The infrastructure in Kenya is by no means shabby. The seaport at Mombasa – located at the East African coast – is linked to the mainland by railways and the Great North Road. Kenya is strategically located for investors wanting to access the East and Central African market. Kenya is also a regional hub for airlines allowing for easy access from and to any part of the world. Kenya has a very healthy political stability in the whole of Africa. This is always favoured by foreign investors. As a result, foreign investment in Kenya is increasing steeply. Kenya’s apparel industry which currently specialises in supplying high volume bulk items, such as trousers, benefited greatly from AGOA. Kenya exports the biggest share of its apparels to the USA alone. In 2013, some 92 per cent of Kenya’s apparel exports went to the United States. Currently, over 40 billion shillings ($400 million) worth of apparels, including jeans and towels, consumed in the US are manufactured in Kenya’s Export Processing Zone (EPZ). This is projected to hit 100 billion shillings by 2018, according to the Industrialisation Cabinet Secretary Adan Mohamed. Kenya’s performance in the global textile market is turning out to be hugely impressive.The Kenyan government is playing more of an active role to bolster Kenya’s performance in the global textile market even more. The government has acknowledged the importance of a strong foothold in the global garments sector. The government’s medium-term economic growth strategy – dubbed Kenya Vision 2030 – has identified the textile and clothing sector as a potential key driver of the country’s industrialisation. According to the Kenya National Bureau of Statistics (KNBS), the Export Processing Zones (EPZ) recorded a 12.1 per cent growth in sales in 2015. The growth was mostly driven by apparel exports under AGOA. The Economic Survey 2016 states, “Total EPZ sales went up by 12.1 per cent from Sh57.2 billion in 2014 to Sh64.1 billion in 2015. The number of local employees increased by 8.7 per cent to 50,523 persons in 2015. The bulk of employment was in the garment/apparel enterprises with a total of 41,548 persons mainly due to expansion of existing apparel and agro-processing farms.”The Kenyan garments industry is formidable in stature. It comprises 22 large foreign-owned companies operating in the Export Processing Zones (EPZs), 170 medium and large companies, eight ginneries, eight spinners, 15 weaving and knitting companies, nine accessories manufacturers and over 75,000 micro and small companies, including fashion designers and tailoring units. However, according to the Ministry of Industrialisation, the performance of the EPZs has been disappointing. It plans to scrap the EPZs altogether and introduce a new model of Special Economic Zones (SEZs) to replace the EPZs. New SEZs are currently being set up in Mombasa, Lamu and Kisumu. The Kisumu facility is aimed at growing export trade within the East Africa Community (EAC) and the Great Lakes region. A special SEZ will also be set up close to the geothermal plants in Olkaria. Manufacturers in the special economic zones will enjoy discounts on power bills because of lower transmission costs from the geothermal plants in Olkaria to the industrial hubs. Another perk of the SEZs is that they shall be subject to a reduced corporation tax of 10 per cent for the first 10 years and 15 per cent for the next 10 years.With an estimated 30,000 workers, Kenya’s apparel industry – valued at $330million a year in 2014, according to the Kenya Association of Manufacturers – is still relatively small compared to Bangladesh which has a $28 billion RMG export market and the industry employs around 4.4 million people. However, the Kenyan textile industry is most definitely heading in the right direction. The struggles of the Asian Tigers in the global markets have presented Kenya a chance to gain a strong foothold in the global market. So far, Kenya has fully utilised this opportunity. If Kenya can develop and improve its infrastructure, it is expected to achieve a permanent spot at the top of the global textile market. China, the world number one apparel player, has been working closely with the African industry. We expect that Bangladesh RMG industry, the second largest global exporter, can and should play a collaborative role with the Kenyan as well as African RMG and textile industries.

Mehdi Mahbub is the President of Bangladesh RMG Centre.